I have removed the belt and cover but cannot remove the water pump. (I am replacing the water pump too).

I have removed the belt and cover but cannot remove the water pump. (I am replacing the water pump too).

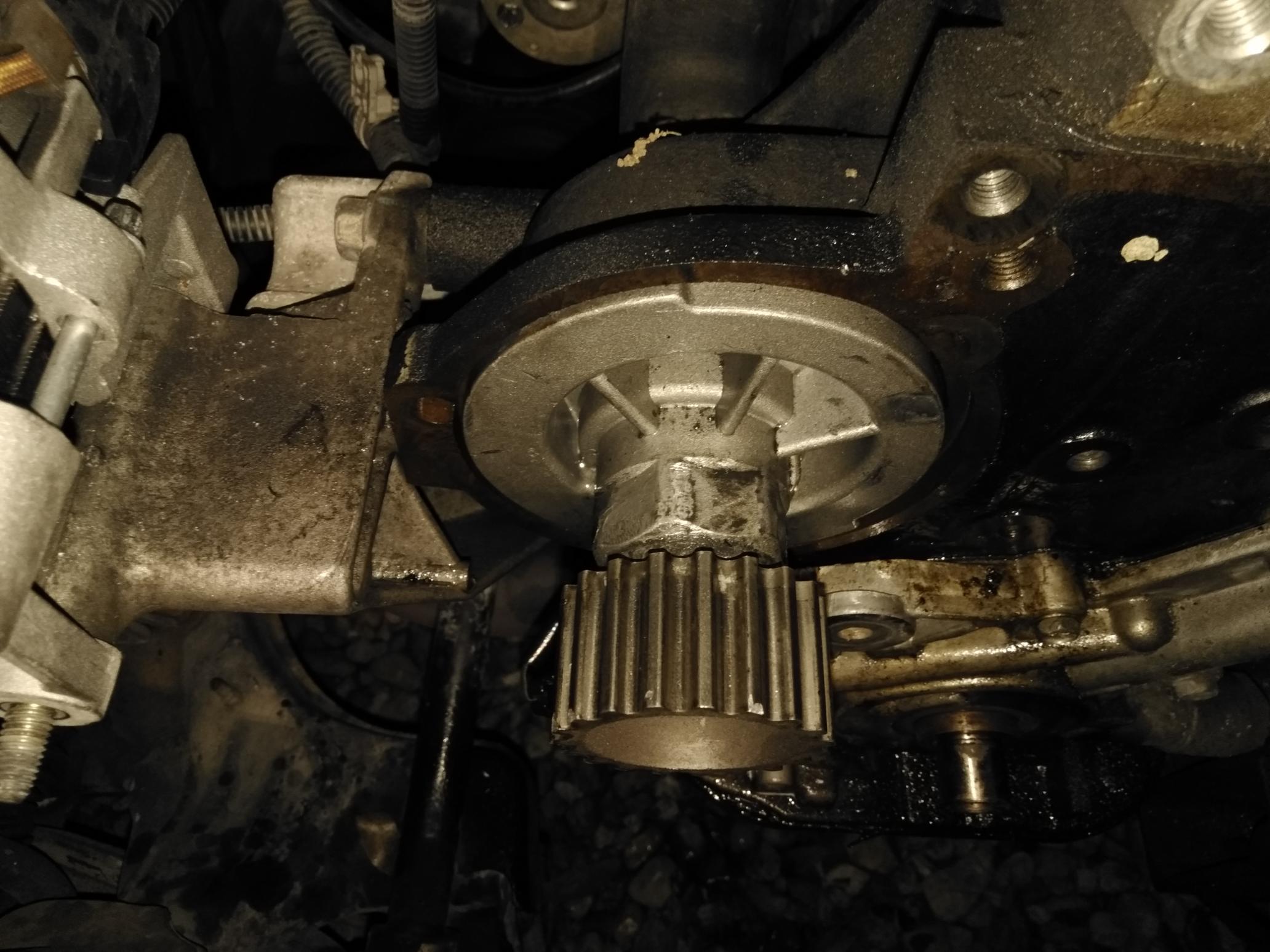

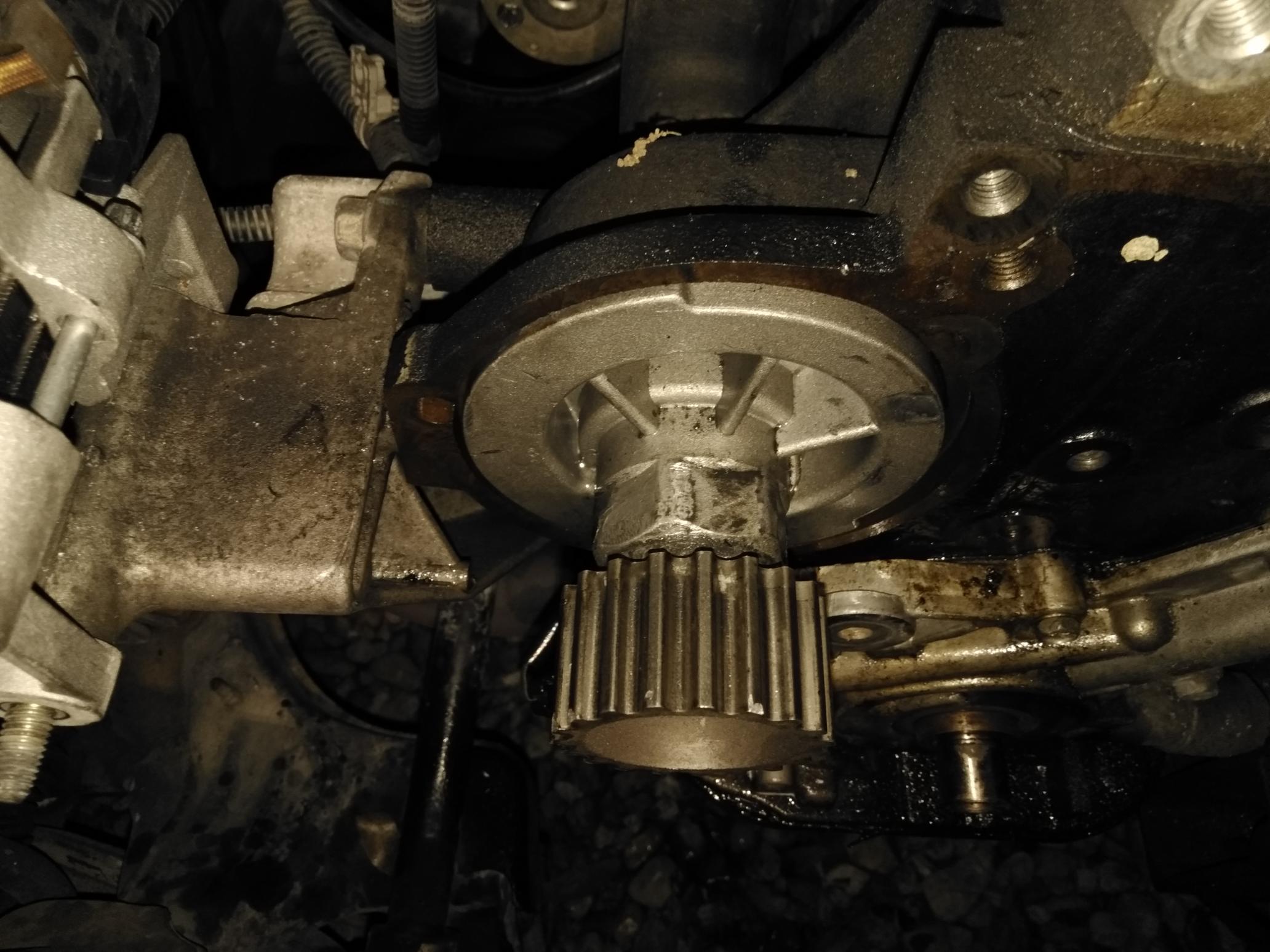

Percussive maintenance removed the water pump. Mounting surface was cleaned and remounted the pump, cover, and pulleys.

Tried correcting for the five counter clockwise jumps. Did not correct it.

How do I correct my timing?

edit: I'm thinking the jumps may have happened on the exhaust crank

Last edited by rgansaldi; 06-04-2019 at 04:13 AM.

I'm not sure exactly what you're doing but it would be best to first pin the cams together (with the marks pointing to each other at 9 and 3) with a tool, or perhaps zip ties if you don't have a suitable cam locking tool. Then it will probably take at least a few tries, in order to get the belt properly tensioned with the crank mark pointing directly down at 6, and the cam marks still in their correct alignment. Just keep track of the notches on the belt and pulleys, and make adjustments until it all falls into place correctly with the belt properly tensioned. I've always painted the belt before removing it, and never have had to reinstall the belt using this trial-and-error method, but I can understand how frustrating it might be. Just keep at it, and sooner or later you will get it to cooperate.

So I've got everything aligned and am waiting on the rain to stop so I can continue. Getting the timing right will be challenging.

Not as challenging as I thought it would be. I'm afraid to start the engine because I've been spooked that the valves may be bent. How am I supposed to do the compression test? Should I just get over it and run the engine for it to warm up before the compression test??

First off, let's make sure we're on the same page with this. Do you now have the belt properly tensioned with the water pump/tensioner pulley, and all of the timing marks in the correct positions? If so, then have you been able to do 2 engine revolutions with no resistance while turning? If you're all set with the above steps, then just start it up and see how it runs. Any valve damage that might have already happened can't be undone, and additional damage is immaterial because it's going to need a valve job anyway. If it won't start, or runs poorly, then move on to the compression test.

Yes. Everything has been reassembled and the belt is properly tensioned.

The engine turns for the two rotations but there is resistance. When the key is turned to on position the starter (or primer, I'm not sure what makes the noise) makes an irregular noise and the car will not stay on. It putters itself out of power as if the valves are open during the explosion.

I'm expecting to have to replace the whole cylinder head, yes? I looked down the spark plugs and saw no damage to the piston heads but I don't really know if I would be able to see anything.

There is one more issue, most of my screws were already pretty stripped before I took them off, probably from the last mechanic. Now that I've put them back together I'm afraid they may be stripped enough to where I cannot remove them, how could I deal with this?

Resistance is not the word I should have used, because there is always some of that while turning the engine by hand. It's really a question of continuing to turn without it feeling like it's hitting something solid. I assume you didn't get anything like that?

Is everything required to run back in place correctly? Did you get the harmonic balancer torqued at least close to spec?... When the key is turned to on position the starter (or primer, I'm not sure what makes the noise) makes an irregular noise and the car will not stay on. It putters itself out of power as if the valves are open during the explosion. ...

If valves were bent you can either rebuild the existing head with new valves, or buy one that's already been rebuilt. Your choice.... I'm expecting to have to replace the whole cylinder head, yes? I looked down the spark plugs and saw no damage to the piston heads but I don't really know if I would be able to see anything. ...

Which screws are your talking about?.... There is one more issue, most of my screws were already pretty stripped before I took them off, probably from the last mechanic. Now that I've put them back together I'm afraid they may be stripped enough to where I cannot remove them, how could I deal with this?

Before deciding on what to do, I recommend doing 2 things. First do a compression test, in order to confirm it's low. And, if the compression is in fact low, then you should remove the harmonic balancer one more time, in order to confirm that the timing marks are still right on. It's not unusual at all to make some small mistake and have the timing be off a notch or two. Do all of the relatively simple diagnostics, before getting into the big stuff.

No, it never seemed to be hitting something solid, but it felt that for parts of the rotation it was harder to rotate and then once passed that the engine would rotate freely for about a 1/4 of the camshaft sprocket with no resistance.

If by required you mean everything. I just reassembled everything so the alternator would run.

I'm not sure how to get the torque right, I just made it as tight as I could, without being unreasonable, with my breaker bar. I keep hearing about people saying that torque wrenches are not accurate. Is this your experience? Can you explain how to get it right?

I would choose to remove a whole head from a junkyard vehicle. Would that not be appropriate?

Specifically, one coolant thermostat screw, one hex water pump retention screw, one engine mount screw.

Aren't I supposed to run the engine before doing the compression test? The engine won't run.

I'm guessing tightening the water pump offset the crankshaft position.

No, it never seemed to be hitting something solid, but it felt that for parts of the rotation it was harder to rotate and then once passed that the engine would rotate freely for about a 1/4 of the camshaft sprocket with no resistance.

If by required you mean everything. I just reassembled everything so the alternator would run.

I'm not sure how to get the torque right, I just made it as tight as I could, without being unreasonable, with my breaker bar. I keep hearing about people saying that torque wrenches are not accurate. Is this your experience? Can you explain how to get it right?

I would choose to remove a whole head from a junkyard vehicle. Would that not be appropriate?

Specifically, one coolant thermostat screw, one hex water pump retention screw, one engine mount screw.

Aren't I supposed to run the engine before doing the compression test? The engine won't run.

I'm guessing tightening the water pump offset the crankshaft position.